The development of skyscrapers is a process which had its birth in the ancient world, with the construction of such wonders as the pyramids of Egypt and the Great Lighthouse Pharos of Alexandria. Yet these ancient structures remained the exceptions to the norm of structural height until the dawn of American industrialization. Throughout most of human architectural history, cathedrals and temples were the largest structures to be built, but their heights were limited by the engineering limitations of the time. Today, skyscrapers are an ordinary feature of most modern industrialized cities. There were countless advances in engineering over the centuries which led to the development of modern skyscrapers, but none so influential as those in the late 19th and 20th centuries. I will explore a few main factors which contributed to the ability to build modern skyscrapers which have become such a necessity in modern industrialized cities.

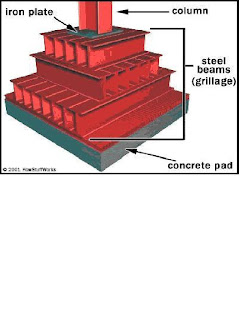

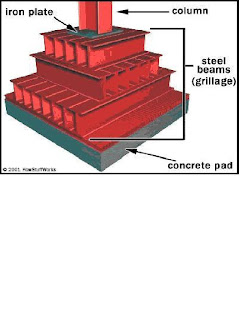

The primary factor which has allowed engineers to overcome the boundaries of building tall structures is the use of steel frames. In the past, attaining any significant height required that a structure’s base be wide to compensate for the increase in the force of gravity created by the weight of the upper levels. This situation meant that as the height of a structure increased, its base had to increase by an increasingly larger factor. The layout of modern cities does not provide the space for such buildings to be erected, and so an alternative is necessary. The use of steel frames (preceded by iron frames) allows for very high construction with no need for a large base. A steel skeleton of rails, riveted together with steel plates, and connected to massive steel columns is what makes up the frames of average skyscrapers today. The huge columns, encased in concrete, are what support the brunt of the force of gravity acting on a building. Functioning like a spine at the core they channel the gravitational forces down through the frame and into the piled foundation below, which is supported by the bedrock beneath. The support structure of some buildings, such as the Sears Tower, is located on the outer perimeter of the building. This so-called “hollow tube” design works in much the same way. (Wells 20)

Skyscraper foundation support (several of these hold up the main columns): Photo from howstuffworks.com

Skyscraper foundation support (several of these hold up the main columns): Photo from howstuffworks.comGenerally, all of the steel support structure is coated in fire-resistant material to ensure that it is protected from warping under extreme heat. The “flimsy fire cladding” (Wells 19) of the steel structure was a factor in the collapse of the World Trade Center towers during the terrorist attacks of September 11th, 2001. It is believed that the impact of the hijacked airplanes largely stripped away this coating, and exposed the superstructure to fire. Once weakened, the beams gave way and resulted in unequal distributions of weight onto lower beams, which were not designed for the strain and collapsed in a domino effect.

The physics associated with the support systems of skyscrapers is complex and fascinating. Virtually every aspect of this science is applied in the design and construction of the supports. The force of gravity, as mentioned above, must be considered thoughtfully when designing the foundation, so that its surface area distributes the weight of the structure effectively. The frictional forces between the steel and concrete foundations and their surroundings must be assessed as well for the distribution of weight. Compressive and tensile strengths of both steel and other materials used in construction must be known in order to assure their proper use and maintain structural integrity. Thermal expansion characteristics of all the supporting material must be known in every conceivable temperature they may endure.

Additionally, buildings must be constructed so that they can be subjugated to natural forces and still maintain structural stability. Wind is prime among these forces. A building must be able to withstand the forces associated with high winds; a problem which must be addressed with care in the tallest of buildings, as wind pressure increases by a power of three with height (Wells 15). Skyscrapers built in earthquake zones are particularly complex. A thicker, stronger-than-normal internal structure is required, as well as complex dampening systems of springs and flexible materials which absorb and distribute the kinetic energy of earthquakes, maintaining the vertical equilibrium of the building.

Today’s skyscrapers, though enormous, are limited by the imperfections of human technology. We can only build them so high. Matthew Wells describes the theoretical vertical limit of a skyscraper, using current building materials, as being 18 kilometers high. However, due the deficiencies of construction, and the unpredictability of environmental forces, he sets the practical limit at 1.60 kilometers. And yet, as of today, we have yet to achieve more than half that height. The Burj Dubai, still under construction, will be the tallest man-made structure on the planet when completed, and stand at 818 meters or more. That is a formidable accomplishment for structural engineers, and yet it is well below the highest conceivable limit.

It is easy to imagine going beyond the heights achieved by modern skyscrapers, (science fiction authors do it all the time), but actually building futuristic supertall structures requires overcoming many engineering obstacles. One of these is the fundamental problem of base size. Steel can only do so much, and eventually we reach the point where we need to augment or buttress the base in order to compensate for the increasing force of gravity applied to the foundations by the materials high up. Just looking at the photo of the Burj Dubai above reveals that the engineers still needed to follow a somewhat pyramid-like design even with the most up-to-date building materials.

Going beyond the 1.6 kilometer mark will require strong materials. Talk has been made about the possibility of using carbon nanotubes, which have a tensile strength fifty times that of steel, and a Young’s modulus five times greater than steel. Maybe with this technology, and some radical engineering practices, the human race will one day see that 1.6 kilometer barrier broken. I am not optimistic, however, of seeing such things come about in my lifetime.

Works Cited

Wells, Matthew. Skyscrapers: Structure and Design. New Haven: Yale, 2005.

http://dvice.com/archives/2007/07/new_record_for_worlds_tallest.php

http://science.howstuffworks.com/skyscraper2.htm

http://people.howstuffworks.com/wtc6.htm

http://www.personal.rdg.ac.uk/~scsharip/tubes.htm

http://www.allaboutskyscrapers.com/skyscraper_design.htm

http://en.wikipedia.org/wiki/Tallest_building

Read more!